Table of Contents

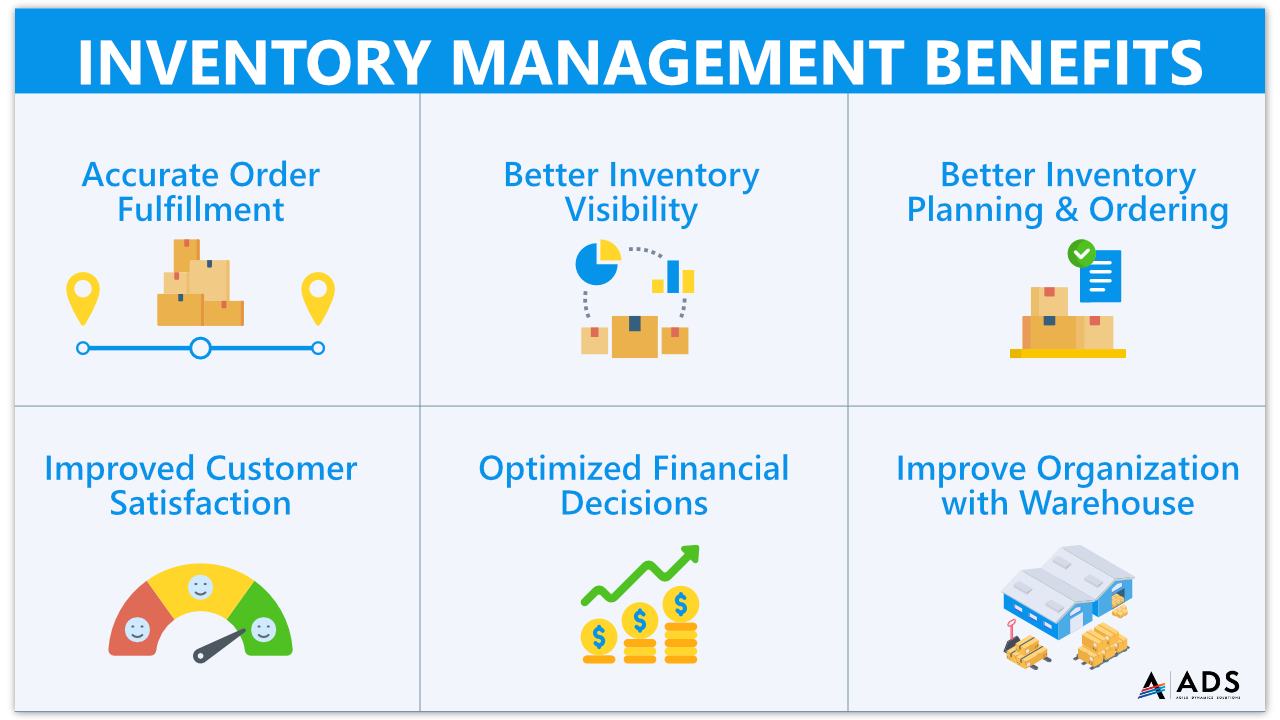

Effective inventory management is critical for the success of any e-commerce business. It ensures that you have the right products available at the right time, minimizes costs, and helps you avoid issues like overstocking or stockouts. Poor inventory management can lead to lost sales, reduced customer satisfaction, and even excess holding costs, impacting profitability. In this article, we’ll explore the key components of mastering inventory management for your e-commerce store and how to implement them to streamline operations and support growth.

Implement Real-Time Inventory Tracking

Real-time inventory tracking is the foundation of effective inventory management. By monitoring your stock levels in real time, you can better manage your supply chain, avoid costly errors, and keep your customers informed about product availability. Real-time tracking also makes it easier to identify patterns in your sales, which can help with inventory forecasting and replenishment.

Inventory Management Software

Investing in inventory management software can streamline the entire process by providing accurate, real-time data on stock levels. Tools like TradeGecko, Cin7, or Zoho Inventory can integrate with your e-commerce platform, allowing you to monitor sales, track inventory levels, and automate reordering.

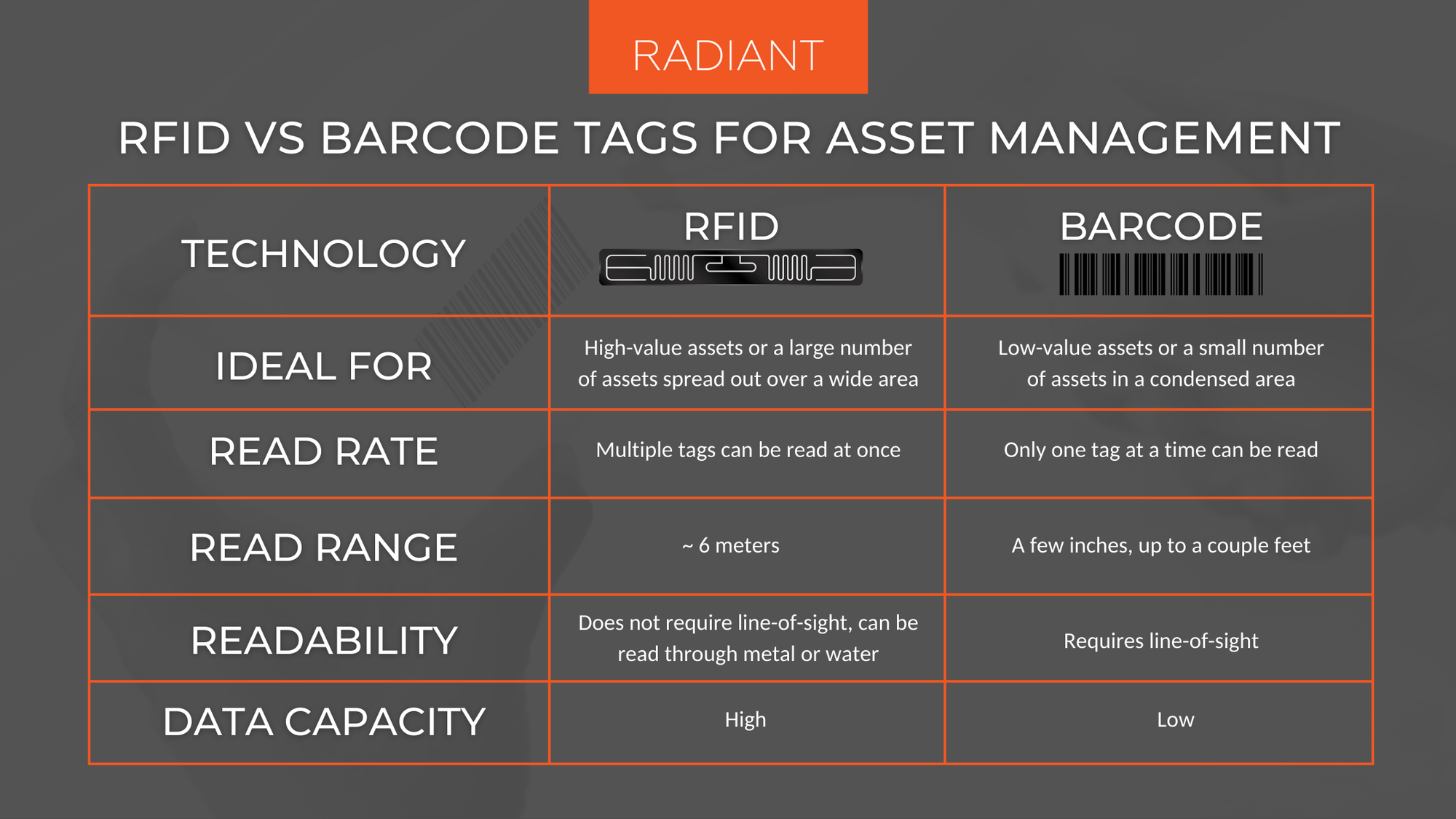

Barcode and RFID Technology

For businesses with large inventories, using barcode or RFID technology can significantly improve accuracy and efficiency. These technologies allow for easy scanning, which updates inventory data instantly, reducing the likelihood of errors and improving stock accuracy.

Optimize Reorder Points and Safety Stock

Setting accurate reorder points and maintaining safety stock ensures that you’re never caught off guard by demand fluctuations. A reorder point is the inventory level at which you should place a new order, while safety stock acts as a buffer to cover unexpected spikes in demand or supplier delays.

Calculating Reorder Points

To calculate your reorder point, determine your average daily sales and multiply it by the lead time required for a new shipment to arrive. This ensures that you’ll reorder at the right time and keep products in stock without over-ordering.

Maintaining Safety Stock Levels

Safety stock should be enough to cover unexpected demand or potential supply chain disruptions. By analyzing historical sales data and considering seasonal demand, you can calculate an optimal safety stock level that prevents stockouts while avoiding excess inventory.

Use Demand Forecasting to Predict Inventory Needs

Accurate demand forecasting allows you to anticipate future inventory needs based on sales data, seasonal trends, and market analysis. Predicting demand helps you manage inventory levels more effectively, reducing costs associated with overstocking or understocking. With demand forecasting, you can make better-informed decisions about which products to reorder and how much to order.

Historical Sales Data

Reviewing historical sales data helps identify patterns in customer behavior, allowing you to adjust your inventory levels accordingly. For example, if certain products consistently sell out during the holiday season, you’ll know to stock up ahead of time.

External Market Trends

Market trends, industry reports, and consumer behavior shifts can also influence your demand forecasting. By staying updated on broader market trends, you can adapt your inventory strategy to match changing consumer demands.

Automate Inventory Management Processes

Automation can significantly improve the efficiency of your inventory management by reducing manual tasks, minimizing errors, and saving time. Automating tasks such as stock tracking, reordering, and inventory updates helps prevent costly mistakes and allows your team to focus on strategic planning and growth.

Automated Reordering

Inventory management software often includes automated reordering, which triggers a new order when stock levels reach a predefined threshold. Automated reordering helps you maintain optimal stock levels without the need for constant monitoring.

Inventory Alerts

Automated alerts notify you when stock levels are low, products are nearing expiration, or there’s a sudden surge in demand. With these notifications, you can respond promptly to inventory changes, minimizing disruptions to your operations.

Implement Inventory Audits and Cycle Counts

Regular inventory audits and cycle counts ensure that the physical inventory in your warehouse matches the data in your system. Conducting audits and cycle counts minimizes discrepancies, improves accuracy, and enhances overall inventory control.

Inventory Audits

Full inventory audits involve counting all items in stock to verify accuracy, usually conducted once or twice a year. While time-consuming, full audits provide a comprehensive view of your inventory and can reveal any major discrepancies.

Cycle Counts

Cycle counts are smaller, more frequent audits of a specific section of inventory. Instead of counting everything at once, you focus on particular products or categories. Cycle counts help maintain inventory accuracy without requiring a full shutdown of operations.

Organize Your Warehouse for Efficiency

A well-organized warehouse layout can save time, reduce picking errors, and improve inventory accuracy. Efficient warehouse organization also enhances productivity and helps you fulfill orders more quickly, leading to higher customer satisfaction.

Product Placement Optimization

Place high-demand products in easily accessible locations to speed up picking times. Group similar products together to make locating and picking them more efficient. Organize your warehouse so that staff can quickly navigate between product zones, reducing order processing times.

Labeling and Categorization

Clear labeling and categorization of products reduce confusion and errors in picking and packing. Use labels, bin locations, or color-coded sections to organize products effectively. This setup not only streamlines operations but also simplifies training for new warehouse staff.

Leverage Multi-Channel Inventory Management

If you sell products on multiple platforms (e.g., your website, Amazon, or social media), multi-channel inventory management is essential. Multi-channel management helps you track inventory across all sales channels in real time, preventing stockouts or overselling and ensuring a seamless shopping experience for customers on each platform.

Centralized Inventory Control

Using a centralized system to manage inventory across all sales channels provides a unified view of your stock levels, orders, and fulfillment needs. This setup reduces the risk of overselling and enables faster response times to stock changes.

Channel-Specific Forecasting

Analyzing sales data for each channel individually allows you to make more accurate predictions about demand. For example, if certain products sell better on Amazon than on your website, you can allocate stock accordingly.

Conclusion

Mastering inventory management is essential for the growth and profitability of your e-commerce business. By implementing real-time tracking, optimizing reorder points, using demand forecasting, and leveraging automation, you can keep stock levels under control, improve customer satisfaction, and minimize operational costs. A well-organized, efficient inventory management system not only enhances the customer experience but also supports sustainable growth. With these practices in place, you can build a resilient and scalable e-commerce operation that thrives in today’s competitive market.

FAQs

What is the most important aspect of inventory management for e-commerce?

The most important aspect is real-time tracking, as it allows you to monitor stock levels accurately, avoid stockouts or overstocking, and make timely decisions about reordering and replenishment.

How do I calculate reorder points?

To calculate reorder points, multiply your average daily sales by the lead time for new inventory to arrive. This helps ensure you have enough stock to meet demand until the next shipment arrives.

Why is demand forecasting crucial for inventory management?

Demand forecasting allows you to anticipate inventory needs based on historical data and market trends. Accurate forecasting helps avoid costly mistakes like overstocking or stockouts, ensuring smooth operations and satisfied customers.

What are inventory audits and cycle counts?

Inventory audits involve counting all stock to verify data accuracy, while cycle counts focus on counting smaller sections more frequently. Both processes improve inventory accuracy and control.

How does automation benefit inventory management?

Automation reduces manual tasks, minimizes errors, and saves time by streamlining processes such as reordering, tracking, and inventory alerts. It allows businesses to maintain optimal stock levels more efficiently.